Tel:+86 1777 8799 416

+86 1571 5183 998

+86 1865 2028 769

E-Mail:ly@htk-gmbh.com

xz@htk-gmbh.com

Address:Wiesenstrasse 21, 40549 Dusseldorf, Germany

• Laser-cut joints, automatic welding and polishes. Screws hidden from view.

• Double walled lid balanced by means of a hinge with front handle, with diagonal opening to 75° which allows the lid to be kept open in any position.

• Tank inbuilt into the surface top by robotic welding, manufactured in AISI-304 stainless steel, with the bottom of the tank in AISI-316L stainless steel.

• Tank filling with hot or cold water by electrovalve, activated with a single switch located on the front panel.

• Tank emptying by 2” safety valve with handle in athermic material and safe and effortless handling.

• Robust and reliable filter for draining the tank manufactured in AISI-304 stainless steel. Easily extractable.

• Controls with protective base and system against water infiltration.

• High temperature enamelled cast iron flue protector.

• Access to the components from the front.

• Machines with IPX5 grade water protection.

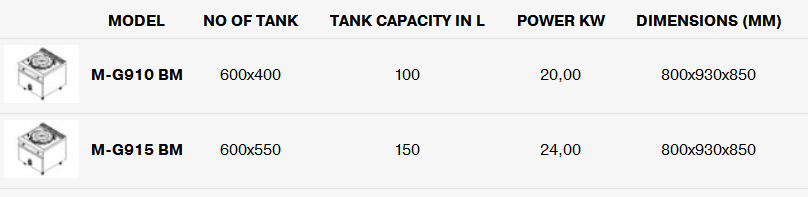

Bain marie gas models

• Bain marie chamber around the tank, with automatic filling system when the machine is connected.

• Automatic chamber level control with quadruple security: pressure switch to control the pressure in the chamber, overpressure security valve, thermostat to limit overheating in the chamber and pressure gauge incorporated into the surface top.

• Automatic flushing of the chamber.

• Heating at the bottom of the pan acts on the water in the surrounding chamber, meaning that the saturated steam generated at a temperature of 107 °C heats the bottom and sides of the tank in a uniform manner. The temperature reached is lower than that obtained with direct heating.

• Inbuilt pan floor to avoid deformations.

• Indicator light to show when the machine is connected and when it is heating.

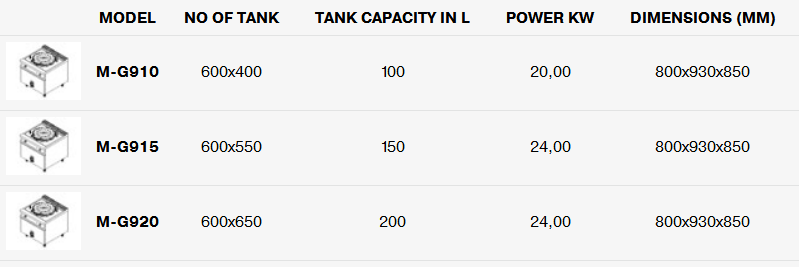

Direct fire gas models

GAS MODELS

• Group of optimised combustion stainless steel tubular burners, controlled by energy regulator and by pressure switch

• Control by energy regulator and by pressure switch, permitting lower water and energy consumption.

• Ignition of group of burners by spark train. There is also an access tube for manual ignition.

• Group of sequentially operating, optimized combustion stainless steel tubular burners, controlled by energy regulator.

• Heating from the burners at the bottom of the pan covers the base in a uniform manner, to give progressive heating of the contents of the tank.

• Option of regulating the heating by the burners, with different degrees of power.

• Ignition of group of burners by spark train.There is also an access tube for manual ignition.

• Indicator light to show when the machine is connected and when it is heating.

Address:Wiesenstrasse 21, 40549 Dusseldorf, Germany

Address:Wiesenstrasse 21, 40549 Dusseldorf, Germany  service hotline:

service hotline: E-Mail:ly@htk-gmbh.com /

E-Mail:ly@htk-gmbh.com / About us

About us Products

Products News

News