Advanced Search:

Contact Us

Hotline:+49 (0)152 5137 2689

Tel:+86 1777 8799 416

+86 1571 5183 998

+86 1865 2028 769

E-Mail:ly@htk-gmbh.com

xz@htk-gmbh.com

Address:Wiesenstrasse 21, 40549 Dusseldorf, Germany

Hot equipment

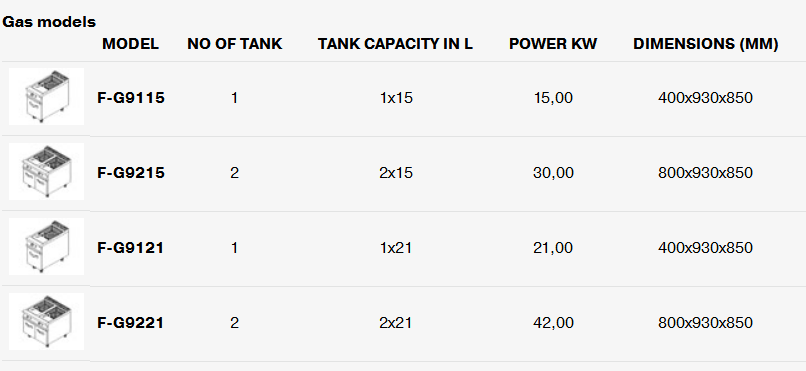

Name:Gas fryers

Details

• Surface tops manufactured in 2 mm thick AISI-304 stainless steel.• Laser-cut joints, automatic welding and polishes. Screws hidden from view.

• Tanks inbuilt into the surface top.

• Cold zone in the lower part of the tank, which helps to maintain the quality and characteristics of the oil in use for longer.

• Thermostatic temperature control between 60 and 200 °C.

• Gas models with three longitudinal heating tubes integrated into the tank.

• High efficiency gas burners.

• Electric models with AISI-304 stainless steel heating elements located inside the tank, which can be swivelled by more than 90° for perfect cleaning.

• High-power machines which heat up very fast and with a high power:litre ratio (up to 1.00 kW/litre in gas models).

• Ignition by spark train for the gas models.

• Safety thermostat in all models.

• Unloading of oil from the tank by means of a robust and reliable ball valve, resistant to high temperatures.

• With individual lids for each tank.

• High temperature enamelled cast iron flue protector.

• Access to the components from the front.

• Machines with IPX5 grade water protection.

• Baskets included:

- 21 litre fryers: 2 small baskets per tank (130 x 330 x 130 mm).

- 15 litre fryers: 1 large basket per tank (250 x 280 x 100 mm).

OPTIONAL ACCESSORIES

- 21 litre fryers: large basket (260 x 330 x 130 mm).

- 15 litre fryers: small basket (125 x 280 x 100 mm).

Address:Wiesenstrasse 21, 40549 Dusseldorf, Germany

Address:Wiesenstrasse 21, 40549 Dusseldorf, Germany  service hotline:

service hotline: E-Mail:ly@htk-gmbh.com /

E-Mail:ly@htk-gmbh.com / About us

About us Products

Products News

News